Introduction of platinum resistance

The platinum wire outer-wound integral sintered platinum resistance patent manufactured by Jinzhou Jingwei Instrument Co., Ltd. is a comprehensive product that combines the advantages and disadvantages of the two technologies. It embodies the advantages of earthquake resistance, stability, small size, no self-heating, long life, and high lead strength.

At present, our company has more than 1,000 customers, all of whom are basically repeat customers. Our products focus on quality. Be confident to make more contributions to all walks of life.

1. integral sintering external wire-wound ceramic platinum resistance

The product is Yang Zhonglin factory director according to the wire-wound platinum resistance anti-overload ability, self-heating is small, in line with the measurement requirements and other advantages, combined with the thin film platinum resistance small size, anti-vibration, fast response and other advantages of a comprehensive design, after a large number of tests in 1998 put into production of new platinum electricity.

Production so far (1998-2011) from the user's use has fully proved the type of platinum resistance of high reliability, long life of excellent quality.

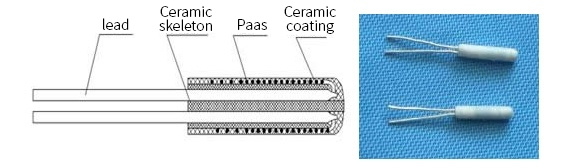

Schematic Diagram of Ceramic Outer Winding Type Platinum Resistance

In structure (as shown in the figure), the platinum resistor adopts a lead wire sintered with the resistor body at the opposite end and led out through the resistor body. The ceramic at the sintering part of the lead wire and the resistor body avoids tensile stress to make the lead wire firm, and the resistor body and the lead wire sintered will not crack under the action of external force. On the other hand, the advantage is that platinum wire is wound on the outer surface of the resistor body and covered with ceramic, and burned into one body, make the response speed of the element fast; Because the platinum wire is divided into the outer surface of the resistor body, the effective heat dissipation area is large, and the thin skin "0.1mm" dissipates heat quickly, the self-heating coefficient is small. Since the platinum wire is constrained in the rigid body of the ceramic, it is not afraid of vibration and has good long-term stability and service life. Moreover, due to the high sintering temperature (above 800 ℃) of the element, the expansion coefficient of platinum wire is much larger than that of ceramic, at the sintering temperature, the platinum wire obtains a larger volume, and with the decrease of temperature, the ceramic solidifies on the periphery of the platinum wire to form a shell. In the use temperature range, the platinum wire belongs to a stress-free free state working in a cavity. If the element is passed into a larger current, only the platinum wire is still within the shell volume after heating volume expansion, without destroying the shell, and the inherent parameters of the element remain unchanged. This is why this type of platinum resistance is competent for hot-wire flow sensors (seeThermal flow sensor)。

1. Compared with thin-film platinum resistance (see thin-film platinum resistance), it has strong anti-overload ability, small self-heating, long-term stability and linearity are better than thin-film resistance, comparable vibration resistance, slightly larger volume than thin-film resistance, and slightly slower response time. However, temperature measurement above 100 ℃ and below 0 ℃ has incomparable advantages in long-term stability and reliability.

2. Compared with the inner wound ceramic platinum resistance (see inner wound platinum resistance), it has obvious advantages in anti-overload ability, anti-vibration ability, response speed, long-term stability, and life span, and the self-heating coefficient is similar.

3. The implementation standard is to JJG229-2010 the resistance that this standard conforms to IEC751:1983-temperature relation formula and indexing table (Pt100 indexing table,Pt1000 indexing table).

4. Selection reference:

Select the original with long life and strong adaptability, and the overall sintered external wire-wound ceramic platinum resistance is a better choice.

Accuracy and temperature measurement range of components:

According to the actual requirements of the site, the temperature range is too large, the processing difficulty increases the waste cost.

● Grade B: (0.30 0.005 ︰ T ︰) ℃, temperature range:-200 ℃ ~ 500 ℃

● Grade A: (0.15 0.002 ︰ T ︰) ℃, temperature range:-150 ℃ ~ 400 ℃

● Class 1/3B: 1/3(0.30 0.005 ︰ T ︰) ℃, temperature range:-100 ℃ ~ 350 ℃

● Class 1/5B: 1/5(0.30 0.005 ︰ T ︰) ℃, temperature range:-60 ℃ ~ 300 ℃

● 1/10B grade: 1/10(0.30 0.005 ︰ t ︰) ℃, temperature range:-30 ℃ ~ 200 ℃

● To obtain an accuracy higher than class 1/10B, a secondary instrument with non-linearization correction must be provided. Can choose thermal resistance "zero temperature drift" high precision intelligent integrated temperature transmitter RS485 output type or JWT4100Z, temperature range, accuracy level is higher than 1/10B level.

● If you want to make high-precision measurements in a wider range, the sensor must use a thermocouple. Thermocouple "zero temperature drift" high precision intelligent integrated temperature transmitter RS485 output type or JWT4100R is a good choice.

4.1, structure and material selection

At present, instruments and equipment are becoming more and more economical and micro-small. Temperature measuring probes are required to be relatively small, such as φ 2.5, φ 3, φ 3.5, φ 4, φ 5, φ 6, etc. Generally, the following design should be improved according to user drawings and technical requirements (accuracy, temperature range, lead type, response speed, pressure, type of environmental medium, sealing, etc.), and the following design should be implemented after both parties reach a consensus.

The leads of temperature measuring elements with 4.2, 1/5B and 1/10B precision are single and four wires below 0.12mm2, without shielding as much as possible to reduce thermal conductivity error.

4.3. The size of the probe has an impact on the accuracy of measuring temperature

Some users require the precision of Pt100 to be very precise, such as 1/5B and 1/10B. According to experience, 1/3B Φ 3 protection tube needs a length of more than 50mm. 1/5B Φ 3 protection tube needs a length of more than 100mm; 1/10B Φ 3 protection tube needs a length of more than 150mm; Otherwise, no matter how accurate the probe is, the inner cavity of the protection tube will be lower than the temperature of the outer surface of the protection tube due to heat conduction of the protection tube, make the originally qualified components out of tolerance. What if the installation space is not allowed to be so long? Use micro-thermocouple type "zero temperature drift" high-precision intelligent integrated temperature transmitter, such as φ1mm, φ1.5 and φ2 probes to make spring-like.

4.4. Response time: The thinner the protective tube, the thinner the tube wall, the faster the response.

4.5. Accuracy and Error List (Reference) Table 1

|

Temperature (℃) |

Class C (2B) |

Class B |

Class A (1/2B) |

Class AA (1/3B) |

Class 1/5B |

Class 1/10B |

Thermocouple integrated temperature transmitter (℃) |

|

-200 |

± 2.60(℃) |

± 1.30(℃) |

± 0.65(℃) |

---- |

---- |

---- |

± 0.30(-measured 200 thermometer interpolation) |

|

-100 |

± 1.60(℃) |

± 0.80(℃) |

± 0.40(℃) |

± 0.265(℃) |

---- |

---- |

±0.20 ———— |

|

-60 |

± 1.20(℃) |

± 0.60(℃) |

± 0.30(℃) |

± 0.200(℃) |

± 0.12(℃) |

± 0.060(℃) |

±0.15 ———— |

|

-30 |

± 0.90(℃) |

± 0.45(℃) |

± 0.225(℃) |

± 0.150(℃) |

± 0.09(℃) |

± 0.045(℃) |

±0.15 ———— |

|

0 |

± 0.06(℃) |

± 0.03(℃) |

± 0.150(℃) |

± 0.100(℃) |

± 0.06(℃) |

± 0.030(℃) |

±0.15 ———— |

|

50 |

± 1.10(℃) |

± 0.55(℃) |

± 0.275(℃) |

± 0.180(℃) |

± 0.11(℃) |

± 0.055(℃) |

±0.15 ———— |

|

100 |

± 1.60(℃) |

± 0.80(℃) |

± 0.400(℃) |

± 0.265(℃) |

± 0.16(℃) |

± 0.080(℃) |

±0.15 ———— |

|

200 |

± 2.60(℃) |

± 1.30(℃) |

± 0.650(℃) |

± 0.430(℃) |

± 0.26(℃) |

± 0.130(℃) |

±0.15 ———— |

|

250 |

± 3.10(℃) |

± 1.55(℃) |

± 0.775(℃) |

± 0.515(℃) |

± 0.31(℃) |

± 0.155(℃) |

±0.15 ———— |

|

300 |

± 3.60(℃) |

± 1.80(℃) |

± 0.900(℃) |

± 0.600(℃) |

± 0.36(℃) |

± 0.180(℃) |

±0.20 ———— |

|

350 |

± 4.10(℃) |

± 2.05(℃) |

± 1.025(℃) |

± 0.683(℃) |

± 0.41(℃) |

± 0.205(℃) |

±0.20 ———— |

|

400 |

± 4.60(℃) |

± 2.30(℃) |

± 1.150(℃) |

± 0.765(℃) |

± 0.46(℃) |

± 0.230(℃) |

± 0.30 ---- |

|

500 |

± 5.60(℃) |

± 2.80(℃) |

± 1.400(℃) |

± 0.930(℃) |

± 0.56(℃) |

± 0.280(℃) |

± 0.30 ---- |

|

550 |

± 6.10(℃) |

± 3.05(℃) |

± 1.520(℃) |

± 1.015(℃) |

± 0.61(℃) |

---- |

± 0.30 ---- |

|

600 |

± 6.60(℃) |

± 3.30(℃) |

± 1.650(℃) |

± 1.100(℃) |

± 0.66(℃) |

---- |

± 0.30 ---- |

|

650 |

± 7.10(℃) |

± 3.55(℃) |

± 1.775(℃) |

± 1.833(℃) |

± 0.71(℃) |

---- |

± 0.30(650 ℃ thermometer interpolation measurement) |

|

700 |

± 7.60(℃) |

± 3.80(℃) |

± 1.900(℃) |

± 1.265(℃) |

---- |

---- |

± 0.40(650 ℃ thermometer software extension) |

|

800 |

---- |

---- |

---- |

---- |

---- |

---- |

± 0.45(650 ℃ thermometer software extension) |

|

900 |

---- |

---- |

---- |

---- |

---- |

---- |

± 0.50(650 ℃ thermometer software extension) |

|

1000 |

---- |

---- |

---- |

---- |

---- |

---- |

± 0.65(650 ℃ thermometer software extension) |

Executive standard: JJG229-2010

Note: The column of thermocouple integrated temperature transmitter in the table is the solution adopted in the temperature range and accuracy level that cannot be achieved by platinum resistance temperature measurement. The accuracy shown in Table 1 is the better accuracy that can be achieved. It is hoped that the thermocouple integrated temperature transmitter with RS485 output will be selected first, and the secondary instrument with RS485 input will realize signal transmission accuracy without loss and various adjustment and control functions.

4.6, precision platinum resistance thermometer

(1) according to 0~650 ℃, according to 0~420 ℃, 0 ~-100 ℃, 0 ~-200 ℃ segmentation, positive temperature and negative temperature can not be mixed, otherwise the stability will decrease.

(2) not according to the accuracy of platinum resistance grade classification, only gives the corresponding thermometer truth table. The resistance values corresponding to the temperature in the truth table are respectively input into the precision detector (such as JT-11A), and the thermometer can be connected to detect the medium temperature in the temperature range of (1), with an error of ≤ 0.02 ℃. The annual stability of the thermometer is ≤ ± 0.005 ℃(5mK).

Defects of 2. Membrane Platinum Resistance

This is currently used more and more fault a called thin film platinum resistance, why use more? Because it can be automated in the process of production, with hours and material costs dozens of times lower, so cheap, businesses can get the benefits of the larger. So the market share is larger.

His disadvantages are poor stability, poor resistance to temperature alternation and narrow temperature range. The fundamental reason is that the ceramic substrate can only use aluminum oxide (AI2O3) with an expansion coefficient of (6.8~8)× 10-6, while the expansion coefficient of platinum is 10.2 × 10-6. Pt100 or Pt100 elements manufactured in normal temperature environment have inconsistent temperature coefficients, so thin film platinum resistors can be used in a small temperature range at normal temperature, the use of a wide range of temperatures results in peeling of the bonding surface of the platinum film and the ceramic substrate due to inconsistent expansion coefficients, which changes the original parameters of the original. This is the direct cause of the instability and reliability of thin film platinum resistors. People will wonder if they can find ceramics with the same expansion coefficient as platinum. Anyway, I haven't found them now. If I find them, I will also dry thin-film platinum resistors.

The second disadvantage is self-heating.

But its outstanding advantages are small size, earthquake resistance, low cost and cheap, and it has advantages in the use of 0-80 ℃ in civilian household appliances (civilian products do not investigate the instability of a few tenths of a degree).

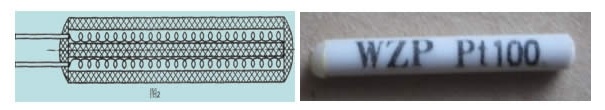

3. inner wound ceramic platinum resistance

This is currently used more than a called inner wound ceramic platinum resistance.

It has two serious structural shortcomings:

1. The ceramic glaze encapsulated at the solder joint between the lead and the platinum wire is subjected to tensile stress, especially when the measurement temperature is high, the junction and strength of the ceramic glaze and the resistor body are easily pulled apart here;

2. The spring-shaped platinum wire is filled with ceramic particles in the two holes of the resistor body as shown in the figure or in the holes, all of which are in the free state of the platinum wire. Therefore, this type of platinum resistance is not seismic, and there are many faults of open circuit and short circuit.

3, but its advantages are: self-heating is not big, no vibration, temperature is not high occasions good stability.

The main products of Jinzhou Jingwei Instrument Co., Ltd. are pt20, Intrinsical Safety Constant Power Thermal Flowmeter, Constant Power Thermal Flowmeter, Oil and Gas Recovery Flowmeter, pt100, Temperature Field Calibrator, High Precision Thermometer, Platinum Resistance, pt100 Platinum Resistance, Thermal Flow Sensor, Thermal Resistance, Thermocouple, pt100 Thermal Resistance, Temperature Transmitter, Temperature Sensor, etc.